With today's advances in technology, most manufacturers […]

With today's advances in technology, most manufacturers are beginning to install electronic turbo actuators in all of their turbochargers. While these expensive pieces of equipment become damaged or worn due to normal usage, you still need to replace them if they are showing signs of failure. These devices provide the additional power your vehicle needs to accelerate and perform well when the other components may no longer be operating as expected.

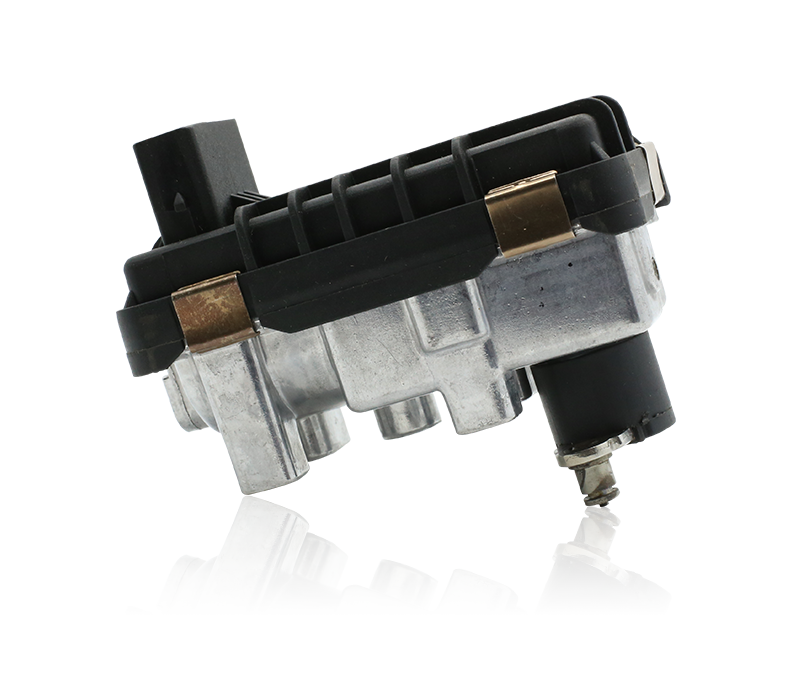

To understand how an electronic turbo actuator works, we must first know a little about the way it is used. The electronic turbo actuator consists of an electric motor, two electronic speed controllers, and printed circuit boards with an electrical interface that interfaces the electric motor with the speed controllers. When the electric motor is spinning at the highest possible speed, the vacuum developed by the driving force of the electric motor pulls the two speed controllers to a centralized location. From this location, the speed of the electric motor can be controlled.

The solenoid that is part of the electronic turbo actuator acts as a safety valve to cut off the pressure from the exhaust gas. As the pressure falls, the pressure in the exhaust gas is allowed to escape and the pressure in the electrical circuit board increases. If the solenoid does not open completely, the pressure will not rise very much and the solenoid will not shut off the exhaust gas flow. This allows the electronic control device to remain effective until the pressure in the exhaust gas reaches a preset value.

There are many different types of electronic turbo actuators on the market. Some manufacturers produce both turbocharger units and solenoid units. The performance specifications for each type can vary quite a bit. Be sure to shop carefully to find the unit that will provide you with the best overall combination of power and efficiency. Once you know what type of electronic turbo actuator you are looking for, you can begin shopping for it. You may be surprised at the great selection available.

One type of variable geometry turbo actuator contains two vats. These vats are typically located very close to the end of the engine's intake port. Because the angle of the vats is variable, they can be positioned so that the airflow hits both sides of the engine at the exact same time. Because the angle of the vats is variable, they also provide more cooling air into the engine, which allows the engine to breathe more efficiently. While these units have been found to boost performance by approximately 15 percent, they do not increase emissions like other styles of turbo compressors do. Since there is no limit on the angle or width of the vats, it is possible to use a combination of variable geometry turbo compressor and solenoids to create greater airflow, but with less power.

Many truck distributors sell a full line of hydraulic and electric actuators, along with multiple styles of ceramic slip-ons. Many styles of electronic turbo pressure pumping units also use hydraulics and electric actuators to increase air pressure in either the BOV or airflow channels. Most distributors of turbo pressure pumping equipment also sell truck specific hydraulic and electric actuators to fit any type of conversion vanes.