When using a turbocharger to modify the engine, […]

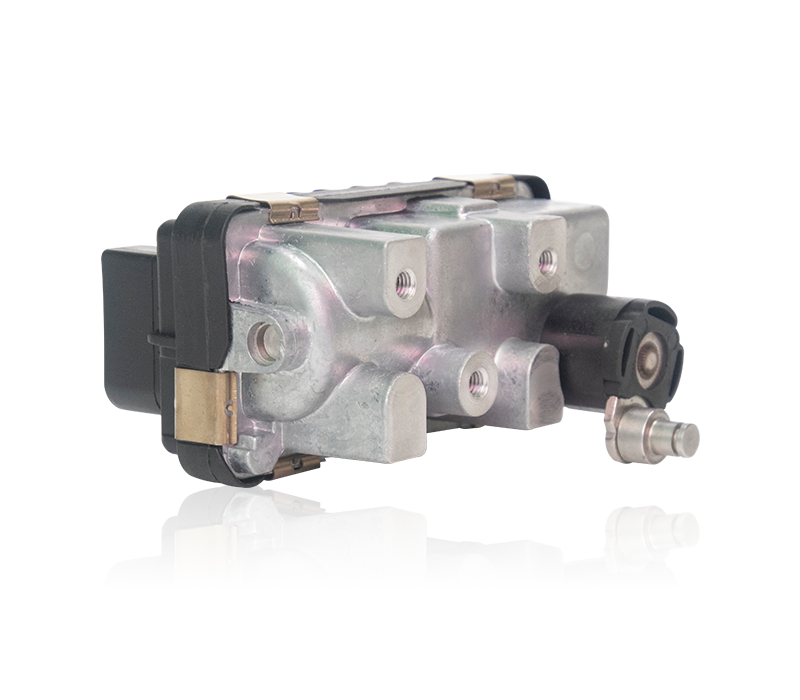

When using a turbocharger to modify the engine, the following seven components should be replaced

1. Replace the large diameter intake pipe. This is not difficult to understand. As the amount of air required by the turbocharger increases, not only should the diameter of the intake pipe be increased, but also the material of the intake pipe should be increased at the same time to ensure smooth intake and intake and to ensure a better turbocharger jobs.

2. Add the impeller. Due to the wide speed range of gasoline engines and large changes in air flow, the turbocharger compressor impellers generally have 12 to 30, arranged in a radial linear curve, and the thickness of the blades is less than 0.5 mm. Generally, the shape of the impeller is a complex three-bend ultra-thin-walled impeller, made of aluminum and made by a special casting method.

3. Install the turbine. The size of the turbines is different, and small turbines are suitable for low engine speeds. When the turbine operates earlier, the start-up speed will be faster. When driving at low speeds, it is best to choose a smaller turbine for automatic transmission vehicles. For large turbines, one is to increase power, and the other is to maintain a high level, high load to maintain increased pressure. When the engine is running at low speed, the large-sized turbine is unstable and will have a response delay.

4. Install the intercooler. The air absorbed by the turbocharger will increase in temperature after compression, and the friction between the air and the intake pipe wall will further increase during the flow process, which not only affects the supercharging efficiency, but also prone to deflagration. Therefore, an intercooler should be installed to prevent this.

5. Add a pressure relief valve. In the high-pressure state, if the throttle is not large, the compressed air will have nowhere to discharge. In this case, the pressure must be relieved. Many turbochargers have safety valves that can directly bypass excess exhaust gas to the exhaust cylinder liner, thereby increasing the response time and protecting the turbocharger.

6. Add ignition and knock sensors. In addition to adding an intercooler to reduce the temperature to reduce the possibility of ignition and explosion, it also adds a knock sensor. The knock sensor detects abnormal vibration waves when knocking occurs, and immediately feeds the information back to the engine ECU control system, which will slightly delay the ignition time. If there is no deflagration, return to normal ignition timing.

7. Install turbo delay fire extinguisher. The operating temperature of the turbocharger is higher than 600℃ to maintain tens of thousands of RPM, which requires reliable lubrication of the turbocharger, which depends on the lubrication and cooling of the engine oil. If the engine stalls after high-speed operation, it will not stop in a short time due to the inertia of the large turbine, and when the engine has been shut down to stop operation, the oil is also round, that is, the lubrication and The cooling time will end, and the result is that the turbocharger is damaged. Therefore, in order to protect the turbocharger, you need to install a turbo delay fire extinguisher.

https://www.fcfuda.com/