The electronic turbo actuator is a key component of a t […]

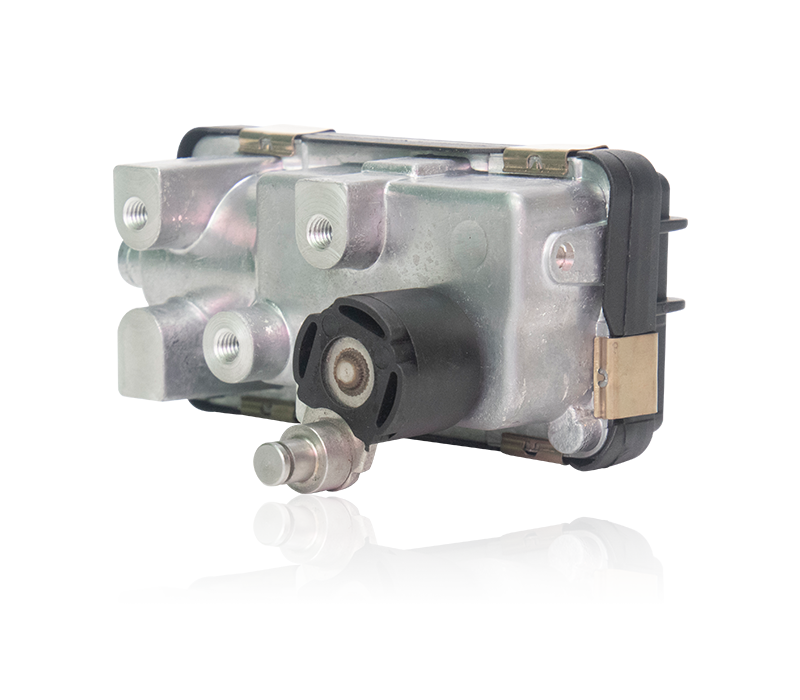

The electronic turbo actuator is a key component of a turbo charged system, such as a vacuum or reciprocating valve or pump. This system employs high frequency driving mechanisms to provide a controlled flow of vacuums. While they may appear simple in nature, they are among the most complex of modern day vacuum systems. In the best of cases, the electronic actuators offer a full suite of diagnostics and monitoring instruments for operation. This is done so that the operator can make adjustments and fine tune without having to open or close any hoses or adjust any other components.

Of the many different types of turbo electronic actuators available, perhaps one of the more popular is the help high-tech actuator. The electronic turbo actuator works best in the most challenging environment possible: right next to your turbo compressor. The extreme vibrations and temperatures from the turbo compressors not only impact the electronic parts inside the actuator, but this stiff vibration and temperatures also affect the mechanical engineering as well. For example, the soft cloth in the air filter brushes can get quite stiff when left in continuous motion, and it will eventually cause premature failure.

If you are a shop owner or a manufacturer who uses electronic turbo actuators, you know that keeping them running smoothly comes with a lot of work. In fact, keeping your turbo actuators in top shape is a constant challenge. As you know too well, these little devils require a steady hand in order to maintain their optimal performance. It is important that you have a regular schedule of tune-ups to ensure that they are always at the peak of performance. Unfortunately though, because of the nature of electronic actuators, it has been difficult for shop owners and manufacturers to keep in regular contact with one another.

Because of the way that turbochargers and turbo compressors work, it's not easy to contact the owners. Without access to the actual turbocharger or the turbocharger system, it will be impossible for you to perform the necessary tune-ups. There has been a lot of recent advancements in technology that make it possible to read the data lines from a vehicle's computer system and to communicate with the boost system within the engine management system. This new technology means that even if you can't physically access your turbocharger, you can still tune it by downloading software which will let you know of any problems with the electronic turbocharger.

When using your new turbocharger, there are other issues that could potentially cause failure. For instance, an extreme cold temperature could cause your turbo actuators to overheat and fail. Also, the high-pressure fuel injected into the engine can cause build up in the fuel injectors, resulting in clogging. If this happens, the fuel line will often be obstructed and you will need to replace your existing fuel injector rather than purchasing a new one.

When looking for an electronic turbo actuator for your boost control, it is important that you choose one that is of high quality. There are some very affordable, low quality units on the market that will simply not perform as well as they should. Make sure that you do your homework and research each of the components that you will be using. There are some great resources online that you can find that will help you learn more about these mechanical components.