High temperature is the big killer of turbocharg […]

High temperature is the big killer of turbochargers

The turbocharger has a simple structure, does not consume the power of the engine itself, and has a high boost value. These factors lead to a powerful advantage of turbocharging. However, the principle of turbocharging makes it have a big hidden danger: high temperature. It is this hidden danger that caused turbocharging to not enter the civilian field for a long time.

There are several sources of heat. The first is the exhaust gas temperature. As we mentioned earlier, the exhaust gas temperature of a gasoline engine can reach 750-900 degrees at full load, and it is nearly 700 degrees under normal working conditions. The exhaust gas will cool down when it drives the turbine to rotate. Where does this temperature go? It is absorbed by the turbine blades.

Secondly, the rotating shaft connecting the turbine and the impeller rotates at a high speed of more than one hundred thousand revolutions, and the friction between the rotating shaft and the bearing will generate a lot of heat. The intake impeller continuously sucks in air, compresses the air, and its temperature rises. These factors add up to make the entire turbocharger in the "hot".

Turbine failure caused by high temperature mainly lies in the deformation and ablation of turbine blades and the failure of rotating shaft strain. Over the years, engineers have come up with various methods to deal with this problem. In general, there are two ways: using more heat-resistant materials and using more effective cooling methods.

Does turbocharging really have "lag"

"Turbo lag" was once a shortcoming criticized by users. The so-called hysteresis is the time required for the engine to output the corresponding power from the moment we step on the accelerator pedal. In fact, all engines will have this lag, just a little bit. Because if you feel it carefully, you can feel it. The moment we step on the accelerator pedal, the engine needs to inhale more air and adjust the fuel injection volume, all of which take time.

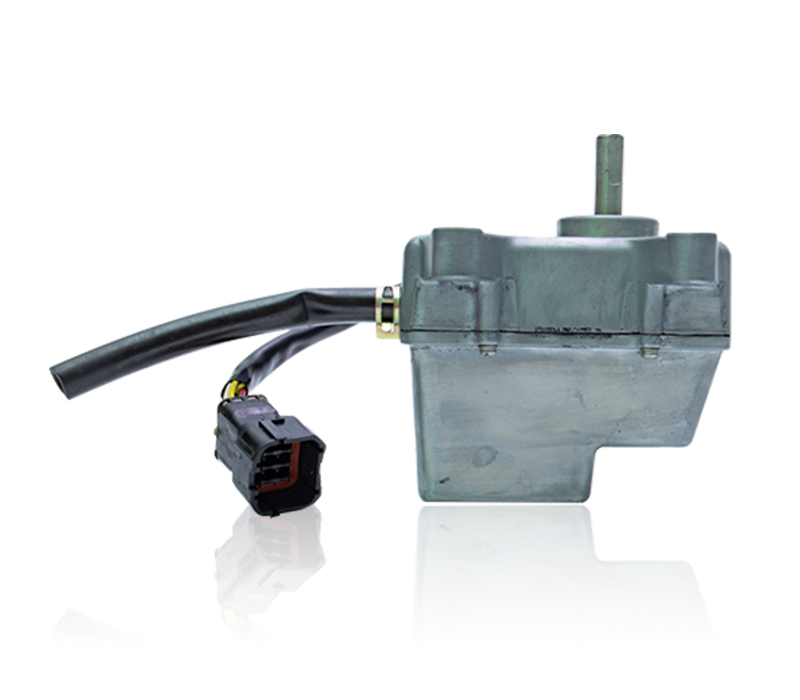

Because early turbocharged engines performed outstandingly in terms of "lag" because they were widely recognized. So where does the hysteresis of the turbine come from? One is the inertia of the turbine rotation, it takes time to accelerate it; the other is the friction between the shaft and the bearing; the resistance formed by the impeller agitating the air. Among these three factors, the resistance produced by the impeller agitating the air is the main one. It is precisely because it takes time to increase the speed of the entire turbine rotor. The larger the impeller of the turbocharger actuator manufacturer, the greater the boost value, the longer the acceleration time required, and the more obvious the "hysteresis".

There are many ways to improve turbo lag. On the one hand, direct injection technology can be used to indirectly improve the torque characteristics at low speeds, so that the engine speed rises rapidly, and the exhaust energy is increased to drive the turbine to reduce turbo lag. On the other hand, by reducing the boost value, the size and weight of the entire turbine rotor can be reduced. On the one hand, inertia and friction can be reduced, and more importantly, the resistance of the impeller can be reduced.

The early turbocharged engines did not have the help of direct injection, coupled with the use of high-charged large turbos in pursuit of performance, the lag phenomenon was quite obvious. The current turbocharged engines generally use direct injection technology, in addition to the use of low supercharged technology, the turbo lag has been greatly improved, and it is almost hard to detect in ordinary driving. It can only be detected when accelerating rapidly. What is the difference between this lag phenomenon and the slow power increase of a naturally aspirated engine when accelerating? (unless you turn on a large displacement naturally aspirated) the "lag" phenomenon of the current low-charged direct-injection turbo engine cannot be compared to the earlier Compared with the high-supercharged engine, it's just that the hysteresis has existed for many years, and it is preconceived.

https://www.fcfuda.com/