The Hella Turbo Actuator is a well-known, high quality […]

The Hella Turbo Actuator is a well-known, high quality kkk turbo engine repair and maintenance product. It is used by almost all dealers for their line of diesel, mid sized, and high performance engines. This type of machine is made to be user friendly, making it a preferred choice among mechanics and hobbyists alike. There are two types of turbo systems available for this machine, namely, the in-line two stage or the rack and pinion (RPS) system. Both types are known to deliver exceptional results and dependable operation.

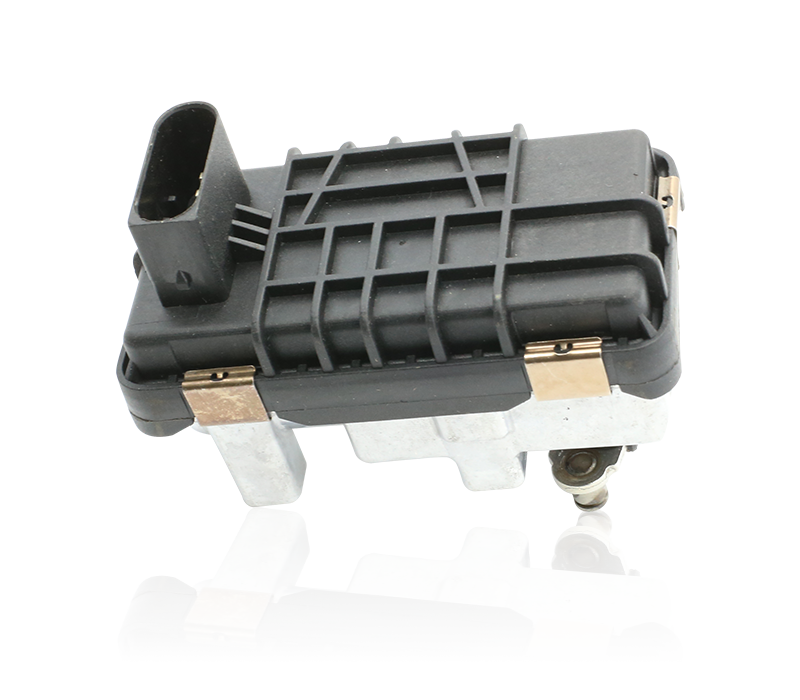

The Hecka Electronic turbo actuators are proven performers that come in both single and two stage versions. These units allow for easy installation and high performance as well. While being more affordable than most hydraulic or mechanical turbo kits, the electronic turbo actuators still perform at high levels allowing for longevity and reliability. Most of these units use either high voltage or high frequency techniques that are known to deliver smooth continuous operation and excellent heat dissipation.

The Hecka turbo actuator is designed with an industry standard, which has helped to make it one of the most sought after units in the industry. The Hecka hydraulic and air driven turbo kits are known for being high quality and efficient. These products have been thoroughly tested and certified for maximum performance and dependability. The Hecka models are sold with a limited lifetime warranty that covers parts and labor. This warranty does not cover modifications, repairs, or alterations.

For best results, when using the Hecka turbo compressors and actuators, you should employ the use of recommended and certified repair manuals. This will help to avoid any costly mistakes and to ensure proper and safe maintenance. You should also follow the recommended flow rates provided in the manual and the required operating temperatures. When using the turbo compressor, it is advisable to install only those accessories that are recommended for the model you own and which meet the recommended standards.

Some important parts of the turbo pressure washer pump include the compressor, electric actuators, electric motor and the valve blocks. The electrical actuators may be either oil-lubricated or grease-free. The lubrication ensures effective operation and optimal performance. The electric motor serves the purpose of increasing suction through increase in compressor horsepower, providing sufficient power for the electric actuators and for the lighting and switching systems.

The valve blocks help to regulate the amount of vapor pressure created during the pumping operation. They also control the flow of gas to the turbo compressor and act as safety valves for the purposes of maintaining pressure. It is advisable to regularly service your turbo pressure washer pump by replacing the blades, belts and valves according to the manufacturer's specifications. You should also clean and maintain your turbo pressure washers to ensure optimal performance and to extend the life span. This will in turn help you to achieve cost savings and optimal productivity levels.