If you own a Volkswagen or other model with a vacuum tu […]

If you own a Volkswagen or other model with a vacuum turbo, you should be able to identify a faulty actuator. It is usually not necessary to replace the entire turbo; however, if it is faulty and not functioning, it will have some of the same symptoms as a faulty vane control ring. Listed below are some of the most common symptoms and how to test them.

The ECU control loop circuit for the actuator is simple. The valve is controlled by the ECU by switching the 12v supply on and off. This process is called Pulse Width Modulation, and you can check if the control voltage is present by placing a volt meter at the electrical plug on the turbo actuator. Turn on the ignition and check if you can feel the control voltage. If there is not, it means the wiring is broken and you must replace it.

The vacuum turbo actuator is a vital part of the car's engine. It's responsible for the smooth functioning of the turbocharger. A faulty can damage the engine, so you should replace it as soon as possible. It may cost up to $800 to replace. In order to avoid this problem, you should regularly service your Vacuum Turbo Actuator. A well-maintained vehicle will last longer and perform better.

The most common type of turbo-powered vehicle is equipped with a Vacuum Turbo Actuator. This device utilizes a vacuum-powered piston to control the angle at which the exhaust hits the turbine wheel. If the ring becomes stuck, the car will enter limp mode. In case of a stuck actuator, you should contact your car manufacturer. They will fix it or replace it. If the valve is stuck, your car will have to go into limp mode.

If the VCDS monitors the movement of the Vacuum Turbo Actuator, then it is faulty. It will display an error code on the dashboard when it fails to respond to a vacuum. If it is faulty, you can try to reduce the vacuum by shortening the actuator rod. However, if the actuator is too short, you will notice boost spikes. In addition, the threads of the adjuster ring may have become dirty or corroded.

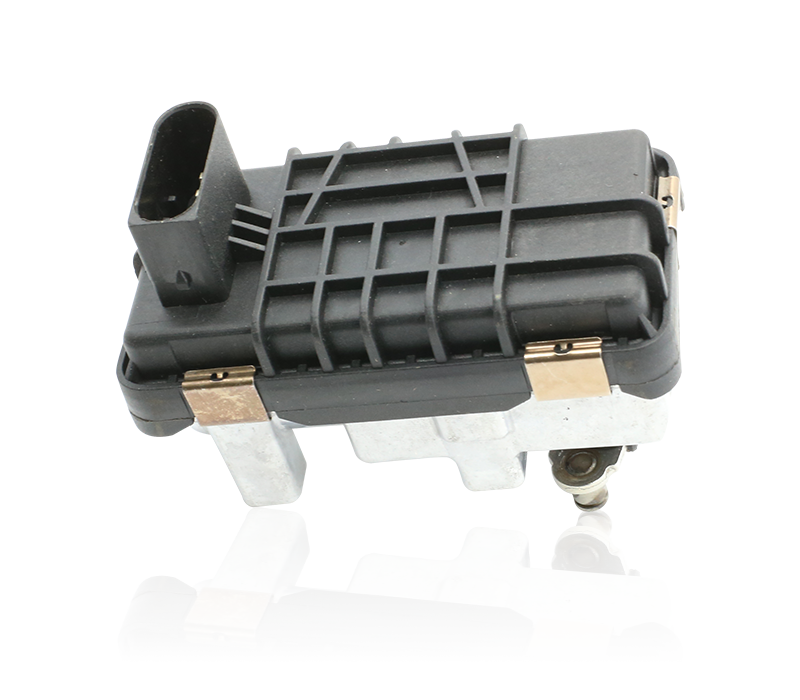

The Vacuum Turbo Actuator works on the same principle as a common drinking straw. A vacuum will pull liquid towards the suction source, which will move the piston. A vacuum turbo Actuator consists of a hermetically sealed chamber with a piston and a diaphragm. The piston moves the actuator rod and transfers motion to the relevant system component. Depending on the size and strength of the vacuum, the actuator is capable of transferring high-speed torques and force without any friction.

If you're looking to replace your Vacuum Turbo Actuator, you should first check its wiring. Broken wiring is one of the most common problems with a Vacuum Turbo Actuator, and the wires must be checked carefully to avoid any dripping of vacuum. Otherwise, you'll end up with a vacuum leak. This can cause the engine to overheat. A good actuator will keep the vacuum in the engine.