With today s technological advances, many manufactures […]

With today s technological advances, many manufactures are beginning to install electronic turbo actuator chips in their high-performance turbochargers. These dynamic parts work in conjunction with your electric motor to regulate the flow of nitrous gas through the turbo. When these units become damaged or worn out through normal use, however, you need to replace them immediately. Here are some of the main reasons why these parts need to be replaced.

The most common reason behind a faulty electronic turbo actuator is that the worm gear has become damaged and therefore is no longer providing a smooth, even pressure along the top of your engine. This damaged portion of the worm gear can be caused by many different things, such as a dirty or broken solvent tip, dirty oil, or dirty contacts. The first thing you should do is open your car's hood and locate the area where the solenoid is located.

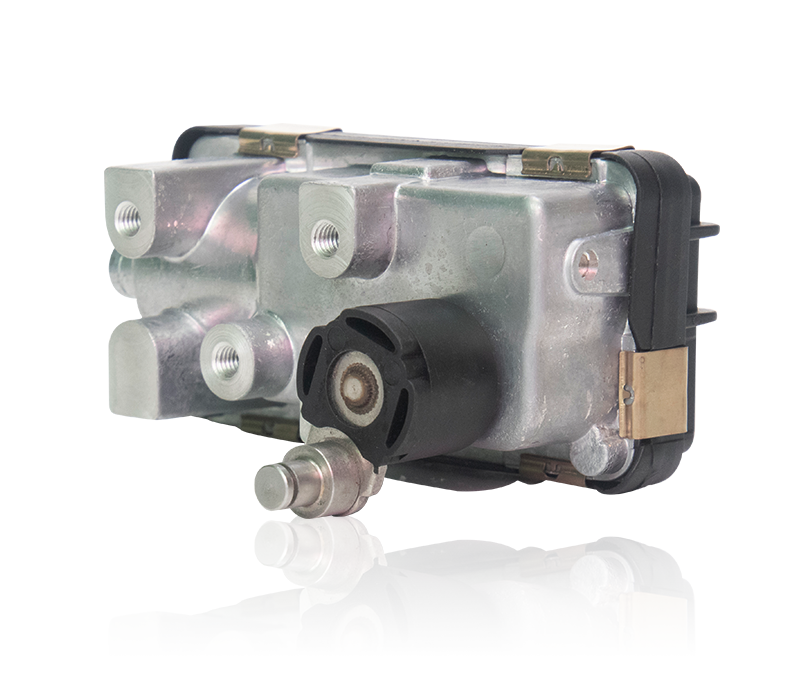

If you look closely at the Electronic Turbo Actuator (ETA) you will see that it is a steel shaft with two screws on either side that are screwed into the lower side of the main cooling fan housing. The two screws connect the solenoid to the electrical power source, which is typically a solenoid plug. Another common way for these units to fail is because of dirty bolts or dirty threads. If you take a short poll from the auto mechanics you are dealing with, they will almost universally tell you to change the valve covers on your turbocharger at least once a year. Another thing that happens time again is that a dirty solenoid can cause your electric motors to cut out. This problem is usually easy to repair and is usually not too expensive.

In addition to dirty bolts or dirty threads, the other biggest cause of failures in modern vehicles is worn out vanes. Vane drag is controlled by a pair of springs on the front of your engine. The purpose of these springs is to provide adequate traction for the vanes on both sides of your vehicle so that your Electronic Turbo Actuator can work properly.

Over time, if your vanes become seriously worn, your Electronic Turbo Actuator arm moves farther away from the center of the engine. The reason for this is because the vanes no longer contact the center of the engine. When this happens, and it often does, your new turbo system will not be able to generate as much horsepower as it did when it was new.

Before I go any further, I want to discuss one important point with you regarding the maintenance of your hecka turbo actuator. To keep your hecka turbo actuator running efficiently, make sure you clean the vanes on a regular basis. The easiest way to clean these areas is with Tung Oil. This is a very inexpensive product that you can buy at any local auto part store. I suggest you purchase some when you first get your new electronic turbo actuator. You can also use Windex, but I personally prefer to use Tung Oil.

If you are interested in saving money, then skip the step above and simply replace your existing high efficiency digital actuator with a high efficiency air-cooled variable geometry turbo pump. While you could always go with a new turbo, the problem with this is that you will lose almost all of the time that you have previously calculated. For this reason, many auto mechanics prefer to upgrade their existing digital actuators with the variable geometry versions. The new variable geometry vanes allow you to maintain higher efficiencies during operation and you can expect to see a large increase in horsepower. These types of variable geometry vanes are also much easier to find at wholesale auto parts superstore.

One final point before we wrap up. Before purchasing your new electronic turbo system, you might want to consider purchasing a high efficiency converter or waste gate. You will also want to make sure that you are going to be able to connect your new turbo to the proper header. A waste gate is a wastegate that actually closes off when the turbocharger is turned off, allowing the engine to expel waste gas under higher pressure than normal. The waste gate also allows the waste gases from the turbocharger to escape through a common carrier, helping to conserve fuel.