A quality turbo injector system can greatly increase th […]

A quality turbo injector system can greatly increase the performance of your high-performance engine. When you are considering which injector is right for your specific application, consider purchasing an Electronic Turbo Actuator. There are many benefits that come with owning one of these electronic injector systems. In this article we will discuss why you should consider an electronic turbo injector system and what the differences are between the various types available on the market today.

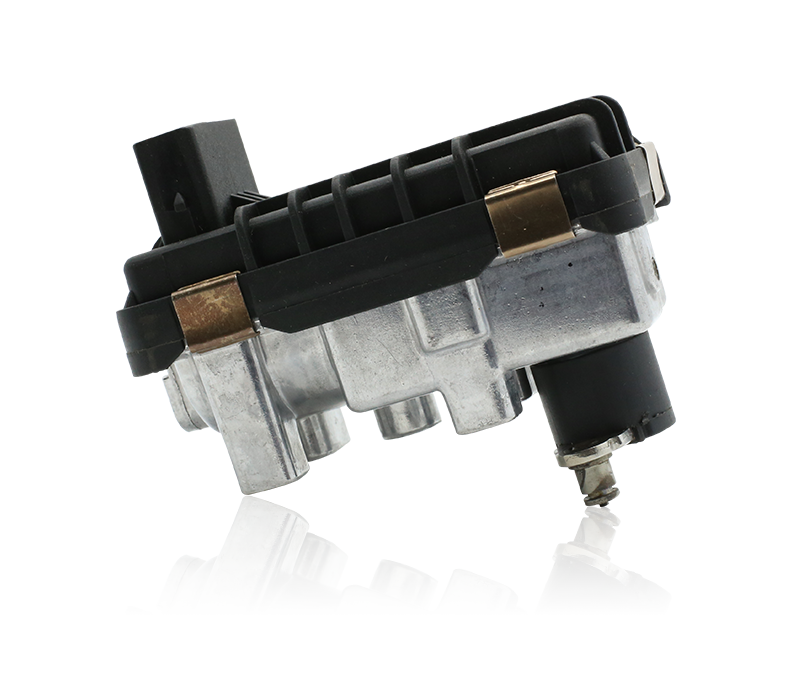

Turbo injectors can be either oil-lubed or electronic turbo actuator driven. Oil-lubed units work well with cold engine conditions while an electronic turbo actuator drives a positive electric motor that is warmed by the combustion of fuel in the engine. You can use either type depending on your application and your injector needs. Electronic Turbo Actuator (ETA) systems produce less friction than oil-lubed units, which results in more consistent power delivery and better waste elimination. They also cost less to operate and require less maintenance to keep operating well.

Most of these type of systems use a small digital LED to show diagnostic trouble codes as they are being used. This is a benefit over the old style black-and-white digits that are displayed in the past. In addition, modern Electronic Turbo Actuator software updates and upgrades frequently can automatically fix problems that are identified by the software without you having to manually initiate the process yourself. New turbo injector system performance upgrades can improve horsepower, throttle response times, fuel efficiency, and emissions as well as other areas such as torque limit, horsepower max, and maximum speed achievable.

Electronic Turbo Actuator systems run on either a single or multiple shaft and most systems will allow for either a two or four-wheel drive vehicle. One of the advantages of using a turbo electronic actuator system is that it is less likely to adversely affect a lifted truck or car. Some older turbo-driven tractors may not have the ability to use the electronic control parts. This is because the former models do not include the right type of worm gear actuators that can engage or disengage the worm gears when the transmission moves.

While the new electronic turbo actuators and other components may cost more initially, the cost savings will more than make up for the cost of purchasing them. You should also consider the fact that during the remanufacturing process, the turbo compressor will be removed from your vehicle and transported to a faraway location for reconditioning. When this occurs, it is likely that the replacement parts will no longer be available.

Once the actuator has been replaced and the boost control valve maintained according to the manufacturer's specifications, you will no longer need to worry about low performance or emission issues. The actuation of these parts is what causes these symptoms in older vehicles. However, with the new, rebuilt turbo electronic actuators, you will experience no loss of power or increased emissions. In fact, the boost control valve itself will be able to work more efficiently, leading to even greater vehicle efficiency and power.