The Hella Turbo Actuator offers excellent value for mon […]

The Hella Turbo Actuator offers excellent value for money when compared with other similar products. It is specifically designed to actuate the regeneration of the compressor, resulting in an increase in engine power. The increase in engine power is provided without sacrificing reliability and efficiency. This means that the performance of the Hella Turbo Actuator can be maximised while maintaining great reliability and performance.

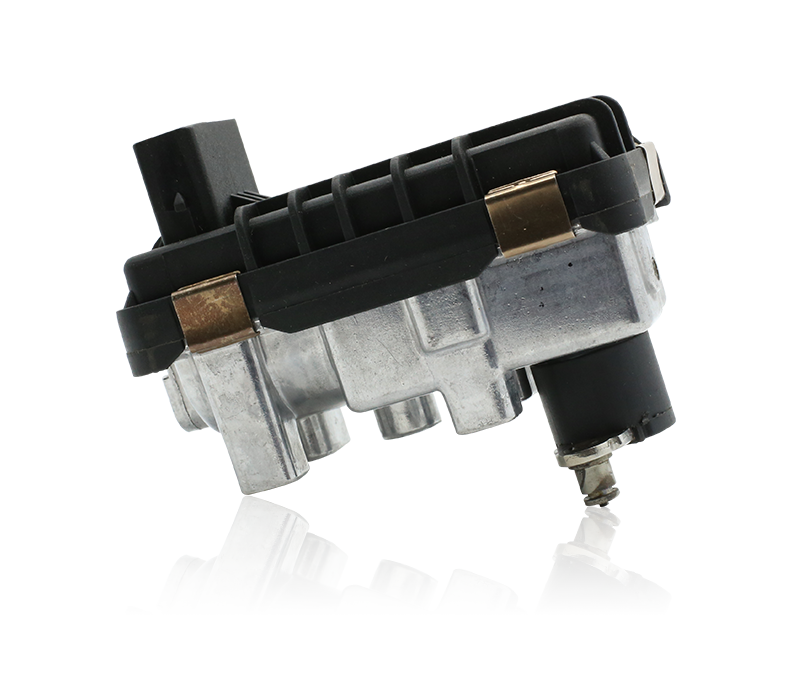

The Hella Turbo Actuator comes in various colours depending on the original finish. The product name can be kept on the outside of the product, or printed circuit board surface. The remanufacturers' information can also be printed on this surface. These components are compatible with almost all makes and models of cars, which feature turbo systems. The original finish and packaging will remain unaffected by use of the Hella turbo actuator. If required, a new connections box or printed circuit board surface can be substituted for the original.

There are several features of the Hecka turbo electric actuators that distinguish them from other similar products. Unlike other hybrid actuators, it features an electric control loop. The loop allows complete control over the operation of the actuator through use of variable geometry and electric servos. The variable geometry allows complete control over the position of the actuator in response to engine load. For instance, if required, the actuator can be positioned closer to the engine or further away depending on engine load.

The control loop and error codes stored on the device are robust and ensure consistent operation. The Hella Turbo Actuator also has a built-in programmable LED display. This is similar to that of some traditional auto electronic repair systems and displays a variable range of parameters including engine speed, pressure, temperature and voltage. In addition, the display also includes separate parameters for intake air control and exhaust air control. These additional features ensure a more complete error code management system. This leads to better control of the actuator and improved reliability.

In addition to improved performance, Hella Turbo Actuator incorporates a new cutting edge technology with its dual VGT sensing capability. This capability ensures full actuation of the actuator at the appropriate time. When using a conventional actuator and connecting a thin metal channel, there is an inherent risk that the actuator will pull the thin metal channel into the actuator body. With the Hella Turbo Actuator, VGT sensors are attached to the top and bottom of the thin metal channel. When a cut is detected, it immediately cuts through the metal channel without damaging the motor itself.

An important feature of the Hella Turbo Actuator system is its automatic adjustment valve. Adjustable valves are always a security precaution because they allow only regulated airflow into the actuator and prevent a dangerous buildup of pressure inside the system. The automatic adjustment valve allows for a constant and progressive amount of airflow into the system. This feature is especially useful for applications requiring a high amount of actuator force for accurate performance.